Background Knowledge:

Most of my work in sensors, has been in designing biofeedback wearable devices, such as WearME Brace. While I also have experience in other sensor systems, such as cameras and hall effect sensors, this post will be a quick rundown of all the specifics needed in order to make a reliable sensor system.

Quick Run:

The first thing to know for sensor design is: what are you trying to achieve? From here we can determine what kind of system we are trying to design. An example is say I just want a raw value that comes in GPS is a perfect example here. A GPS value is just a string that comes from a satellite, in this case the system is pretty clear cut and simple to implement. Now we just take these values and calculate the distance to the satellites, thereby getting the location. Now thankfully most GPS modules do this for you so you do not have to worry about synchronization issues, and detecting the distance. As most sane people use modules and do not make them from scratch.

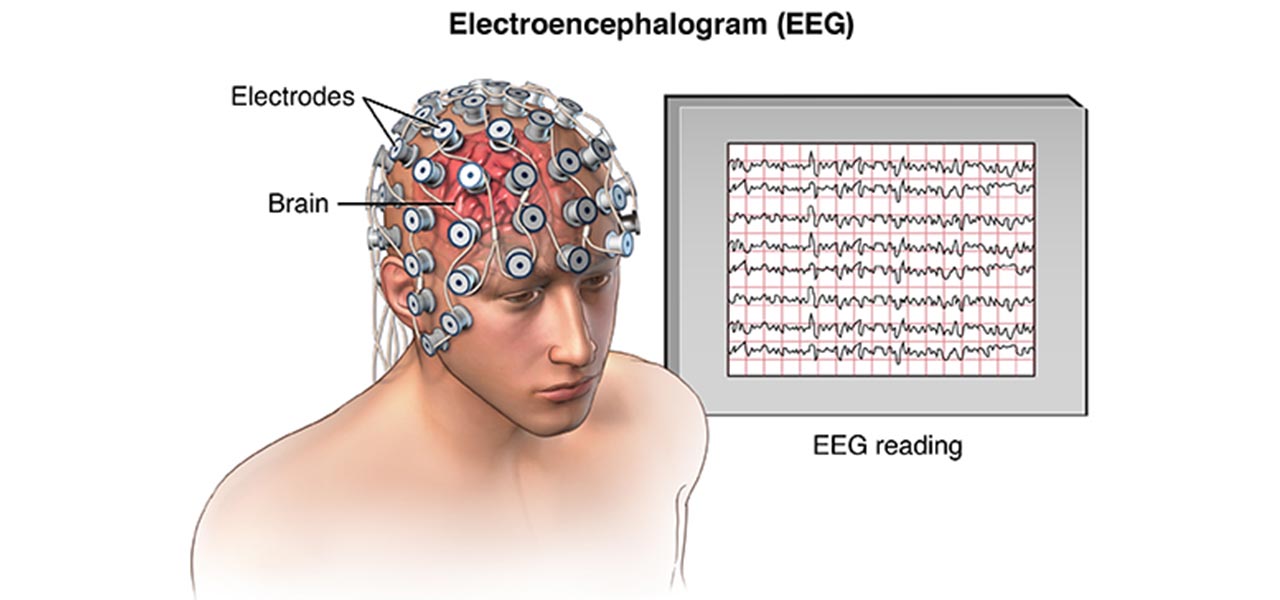

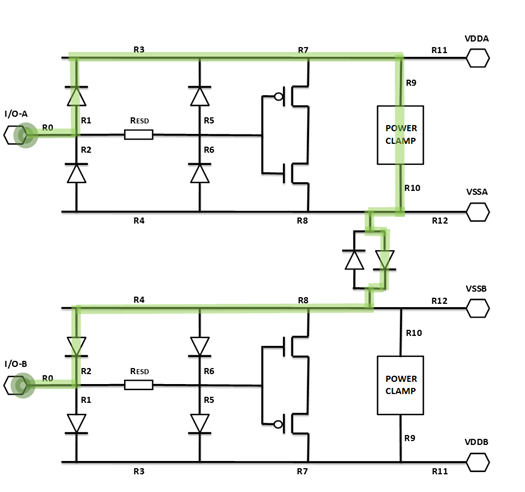

Now not all modules are as simple to use as GPS where all you need to do is just simple text parsing. In quite a few cases it is required to have protection, or signal processing before the signal gets into the MCU. A good example here is an EMG sensor, these sensors are nothing more than electrodes. For this reason it is necessary to ensure that they do not electrocute the individual wearing them. This is done using with Electro Static Discharge (ESD) protection. This and the model to use typically are given in the datasheet, below is an image of a typical ESD protection circuit.

Now to put into perspective here is an image of the sensor circuit that was designed for the WearME Brace.

This board is not the finished board, as the finished one was smaller and more compact. However you can see from here the protection circuit.

Now the bigger problem is one of calibration, each sensor is a different form of calibration. When working at Mycionics camera calibration took 3-4 months before we automated it fully. It is mandatory to ensure a decent calibration otherwise all the work you do will be imaginary, and easily changed based on the environment.

Most Important Tidbits:

- MEASURE YOUR ELECTRICAL COMPONENTS ESPECIALLY SENSORS

- Calibration is incredibly important

- There are ways to use capacitance in between 2 board layers in order to measure touch, this was an incredibly interesting conversation I had

- Use feedback loops to ensure you are getting the correct data